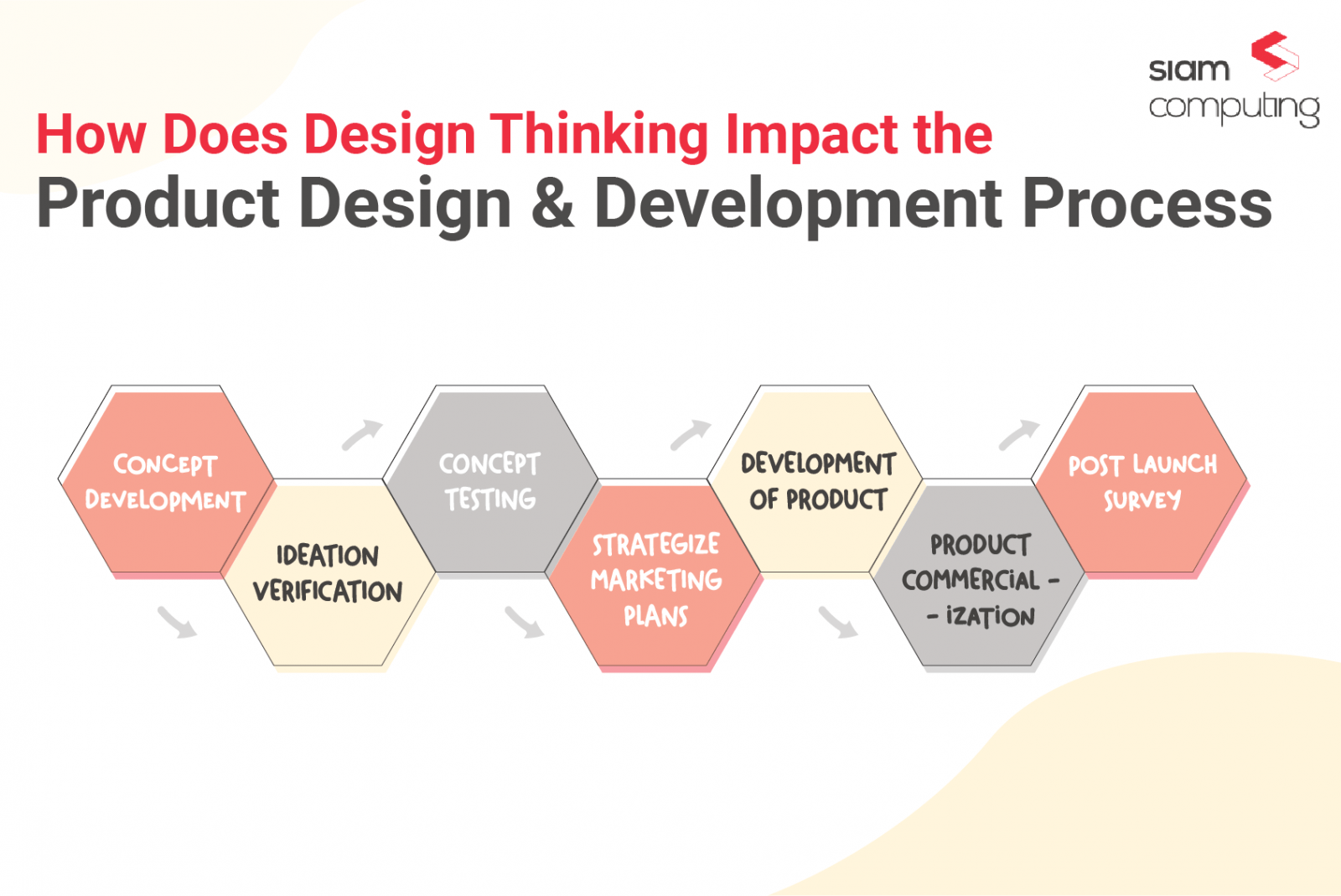

Design process

Conceptual Design

- Study of Architectural Drawings & Beam layouts

- Study of Owners Requirements

- Calculate loads (M&E loads)

- Space planning for Plant rooms / AHU rooms & services shafts

- Planning of Services routing within the layout and plant rooms

- Discussion & finalizing plant rooms and conceptual routes with architects

- Prepare Conceptual design basis report (DBR)

- DBR submission and evaluation by with Client and Architects and conclusion on Services scheme and DBR.

- Proceed for schematic design stage

Schematic Design

- M&E space requirements placement on drawings

- Arriving at M&E services levels for M&E

- Arriving at possible false ceiling levels achievable and co-ordinate M&E services with building structures

- Schematic layouts for piping / cables / etc. (SLDs) along with location of DB closets / electrical rooms / AHU rooms / fan rooms etc

- P&I diagrams for PHE and HVAC system

- Power flow diagram for electrical system

- Prepare schematic design basis report

- Finalize schematic design along with Client and

- Proceed for Design Development stage

Design Development

- Converting Schematic layouts into proper Design layouts on latest architectural layouts

- Co-ordinate M& E layouts with structures and interiors

- Coordinate design workshops along with other consultants and architects for services coordination · Convert SLDs to detailed layouts & detailed SLD for Electrical panels.

- Insert typical detail drawings for plant room, AHUs and other equipment installations

- Detailed typical sections for M&E for interiors and structure coordination

- Proceed for Tender stage

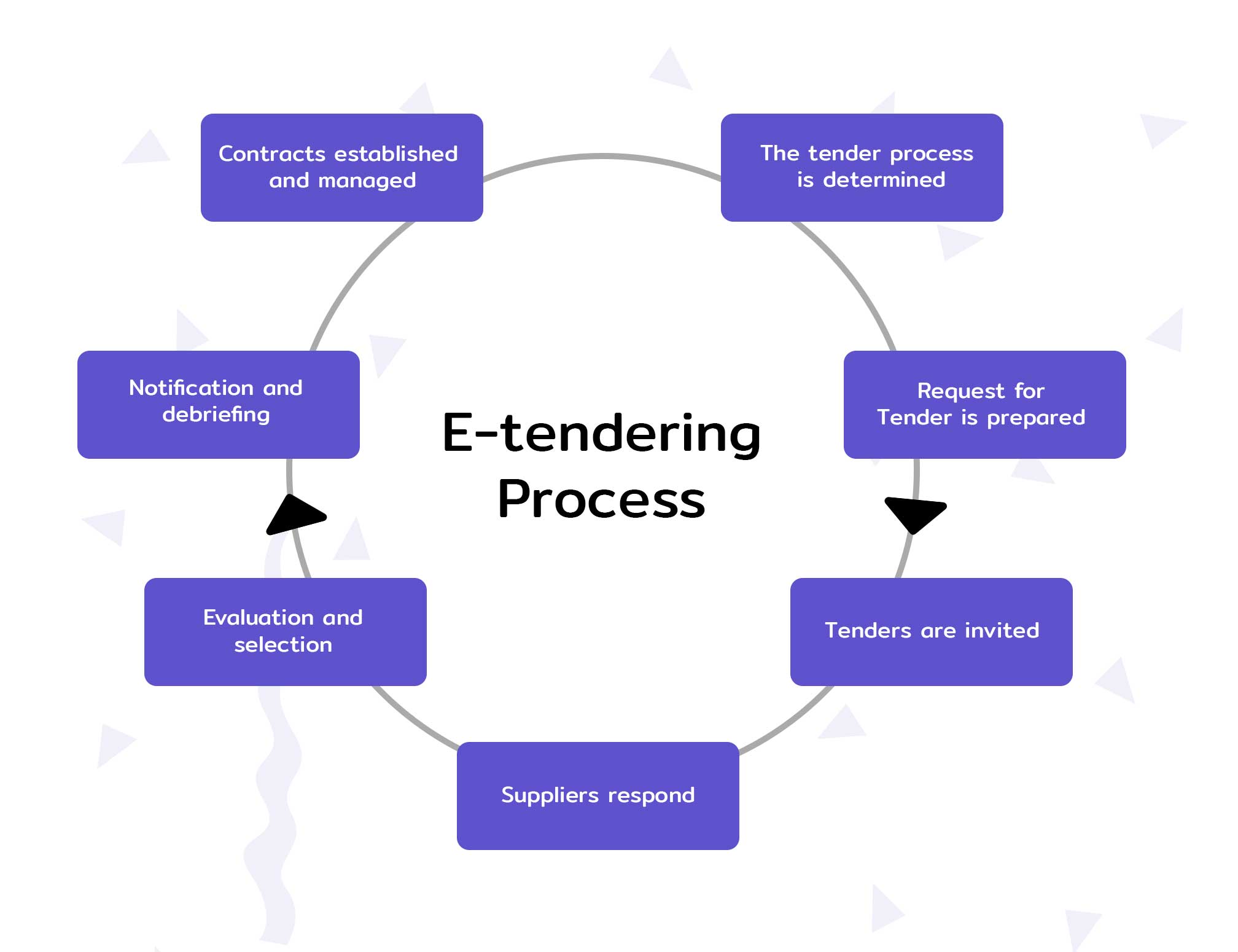

Tender Stage

- Convert DD stage drawings to tender level drawings

- Prepare tender comprising – Bills of quantity / technical specification and commercial conditions if required by client

- Submission of tender document along with drawings to client / architect for necessary approval along with prequalification document (or vendor list) as per the tendering strategy of client

- Assist in shortlisting contactors for tendering

- Assist in Technical and Commercial Evaluation of the Tenders & Comparatives

- Advice Client for finalizing the agencies

- Advice Client for finalizing the agencies

Execution Stage

- Issue working drawings for preparing shop drawings – along with coordination of all services

- Review and Approval of shop drawings from the various contractors along with PMC / client

- Resolve queries / site issues raised by PMC / contractor

- Approvals for technical / material submission from contractor

- Site Visits as required periodically during execution to inspect the workmanship, finishes, material, standards, carryout quality checks, suggest modifications to suit local conditions, suggest improvements and use of alternative materials based on local conditions

- Review of work progress including attending Review meetings

Project Completion/Closeout

- Witnessing of Final Testing and Commissioning.

- Witnessing of IST (wherever applicable)

- Ensure rectifications as per snag list and validate handover documents.

- Checking and Approval of As Built Drawings made by the Contractors.